Watson Webinar Recap: ANSI/ISEA 138: What You Need to Know About the New Impact Standard

ANSI/ISEA 138:2019 fills a very important gap in the standards infrastructure in North America. We have the EN388 standard in Europe and the ANSI/ISEA 105 standard in North America – these standards provide guidance around cut, puncture, abrasion, and chemical exposure. And although the EN388 standard tests for impact, it only tests impact on the knuckles and then provides a pass or fail rating. Thus, before ANSI/ISEA 138:2019, there was never a robust, comprehensive standard to address full dorsal impact protection for industrial gloves.

In this webinar, Rodney Taylor, Watson Gloves’ Director of Sales USA, who also serves as a Trustee of the International Safety Equipment Association (ISEA), Chair of the ANSI/ISEA 138:2019 Work Group and former Vice President of the International Glove Association, takes a deep dive on the impact standard. Christina Yeung, Watson Gloves’ Product Development Manager, also shares the latest impact gloves in the market to suit your needs. For a crash course on the ANSI/ISEA 138:2019 standard, you can read our blog post here. If you’re ready to dive in, then view the webinar recording or read our recap below.

Why Do We Need an Impact Standard?

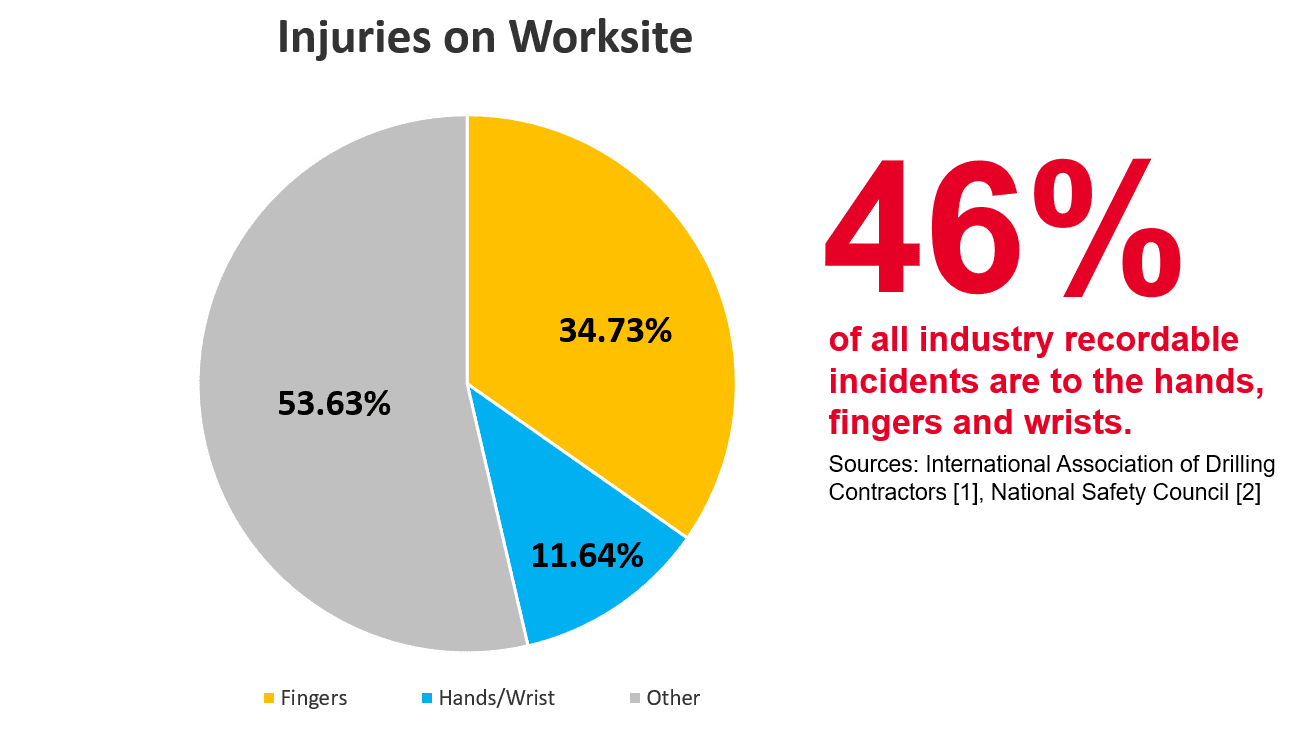

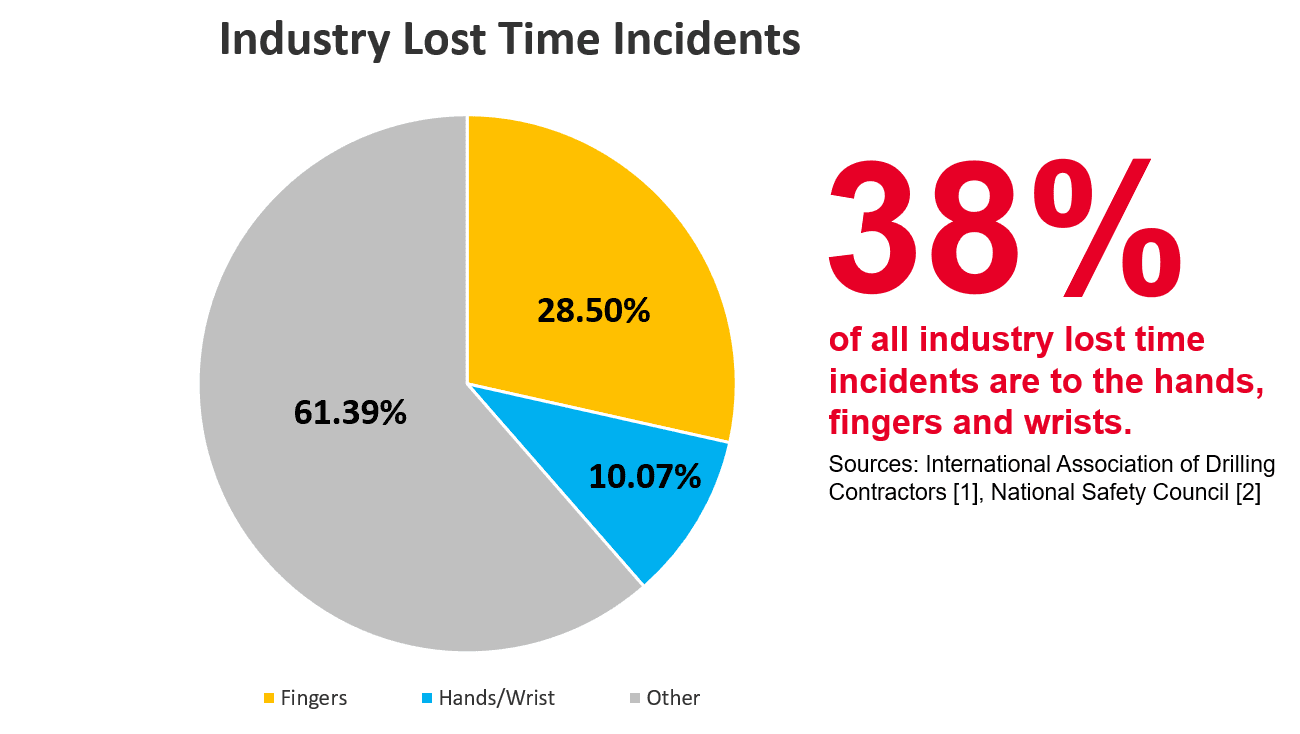

Hand injuries are a major problem in the industry with 46% of all industry recordable incidents related to the hands, fingers and wrists. Of those recordable incidents related to the hands, fingers and wrists, 38% of them lead to lost time incidents. There’s a significant cost associated with these injuries – the estimate for each of these injuries cost about $20,000. Emerging data has shown that a large percentage of hand injuries are impact related. Current data has often cited hand injuries as a cut or slash injury when the actual root cause may be from impact.

Additionally, those who have the responsibility of specifying appropriate PPE have to deal with a flurry of new back of hand impact protective gloves entering the market every other day. It proves to be a challenge for specifiers, as they ask the big question, “what’s the correct measuring stick to compare these different gloves?” End users face the same issue, as they’re unable to objectively compare all these different impact protective products that are out on the market.

Background on the ANSI/ISEA 138:2019 Standard

The ISEA (International Safety Equipment Association) is the primary industrial safety standards development organization in North America. ISEA is linked to ANSI (American National Standards Institute) by serving as the secretariat organization for several ANSI technical standards. That’s why you may see many ISEA standards published as joint ANSI/ISEA standards, such as the ANSI/ISEA 138:2019 standard.

A workgroup of seven ISEA member companies was established to draft a new impact standard, including Rodney Taylor serving as the chair. The ISEA developed ANSI/ISEA 138 with the formal title being the American National Standard for Performance and Classification for Impact Resistant Gloves. It classifies dorsal or back of hand impact gloves by performance and that performance is assessed based on how much energy is dissipated through the glove material.

Impact Testing

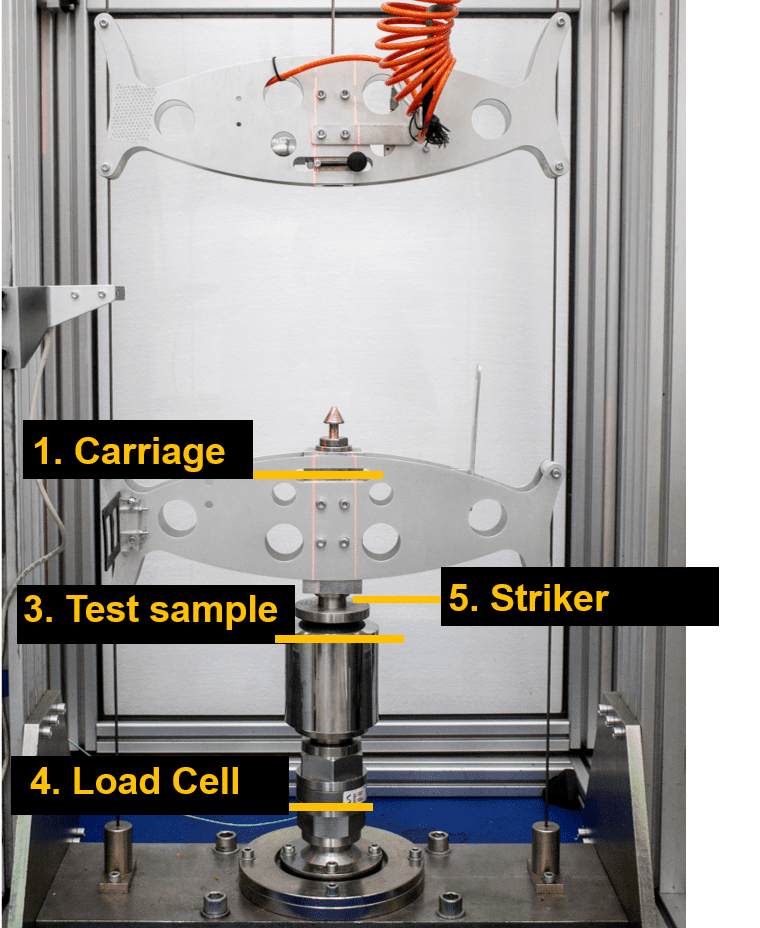

A drop rig is used for glove impact testing. This kind of testing has been used for motorcycle club testing and industrial glove standards in Europe for many years, so this is a proven and reliable test method. A striker makes impact with a force of 5 Joules upon a very specific location of the glove. The peak transmitted force (PTF) is recorded, which is the maximum energy absorbed by the test material. It is important to know that a lower PTF value means more energy absorbed by the test material. That means gloves that absorb the greatest amount of impact would receive the highest performance rating.

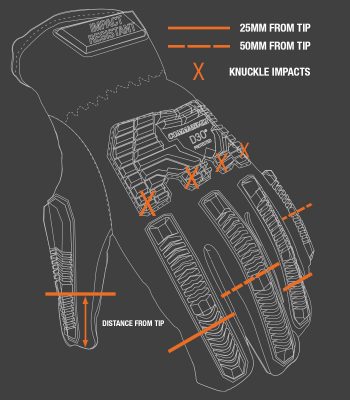

Impact Locations

Both the fingers and knuckles have to be tested for impact. For the fingers, the area 25mm or 50mm from the tip of the glove are tested. In addition to that, all four knuckles are tested, which is identified by the test subject grasping a bar 32mm in diameter with the glove and marking where the peak of the knuckles are. This procedure is important, as that ensures the location of the knuckles are being tested, as opposed to simply where the impact protective material is. In total, the test is repeated 10 times for fingers and 8 times for knuckles.

How is Impact Force Measured?

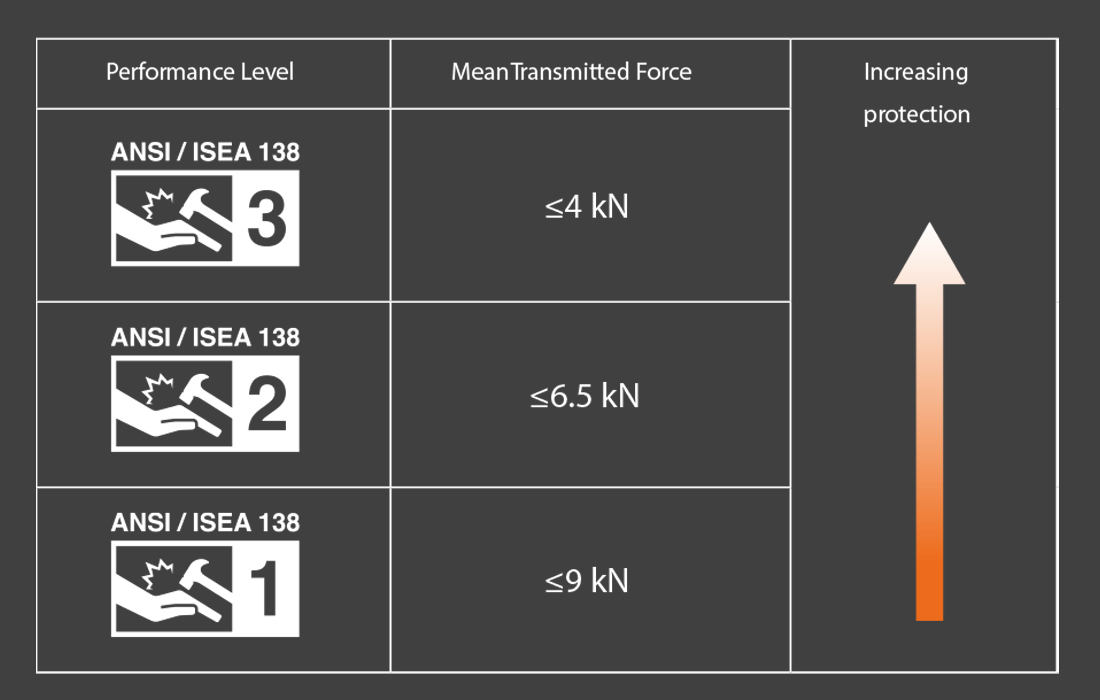

ANSI/ISEA 138 provides 3 performance levels for impact gloves: Levels 1, 2 and 3 – Level 1 being the lowest performance and Level 3 being the highest performance based on PTF measurements using the assessment above. The unit to measure force is Newton (N). Typical impact forces that are encountered in the ANSI/ISEA 138 compliant testing are over 1,000 N, so the unit is simplified to kN, which is equal to 1,000 N.

If an impact test was ran with no sample and had a metal striker slamming against a metal anvil, the impact energy would be about 45 kN or about 10,000 pounds-force. That means for a glove to be compliant, it has to absorb a significant amount of energy. This paints a better picture of the vast impact dissipation that’s necessary to qualify for compliance with the ANSI/ISEA 138 standard.

Marking Requirements

All impact testing must be conducted by an independent test facility; that means manufacturers cannot self certify their impact claims. Additionally, if a manufacturer will be claiming compliance to the impact standard, they must apply the required pictogram marking (Impact Level 1, 2, or 3), so that end users can quickly and easily recognize what performance is being claimed on the particular glove.

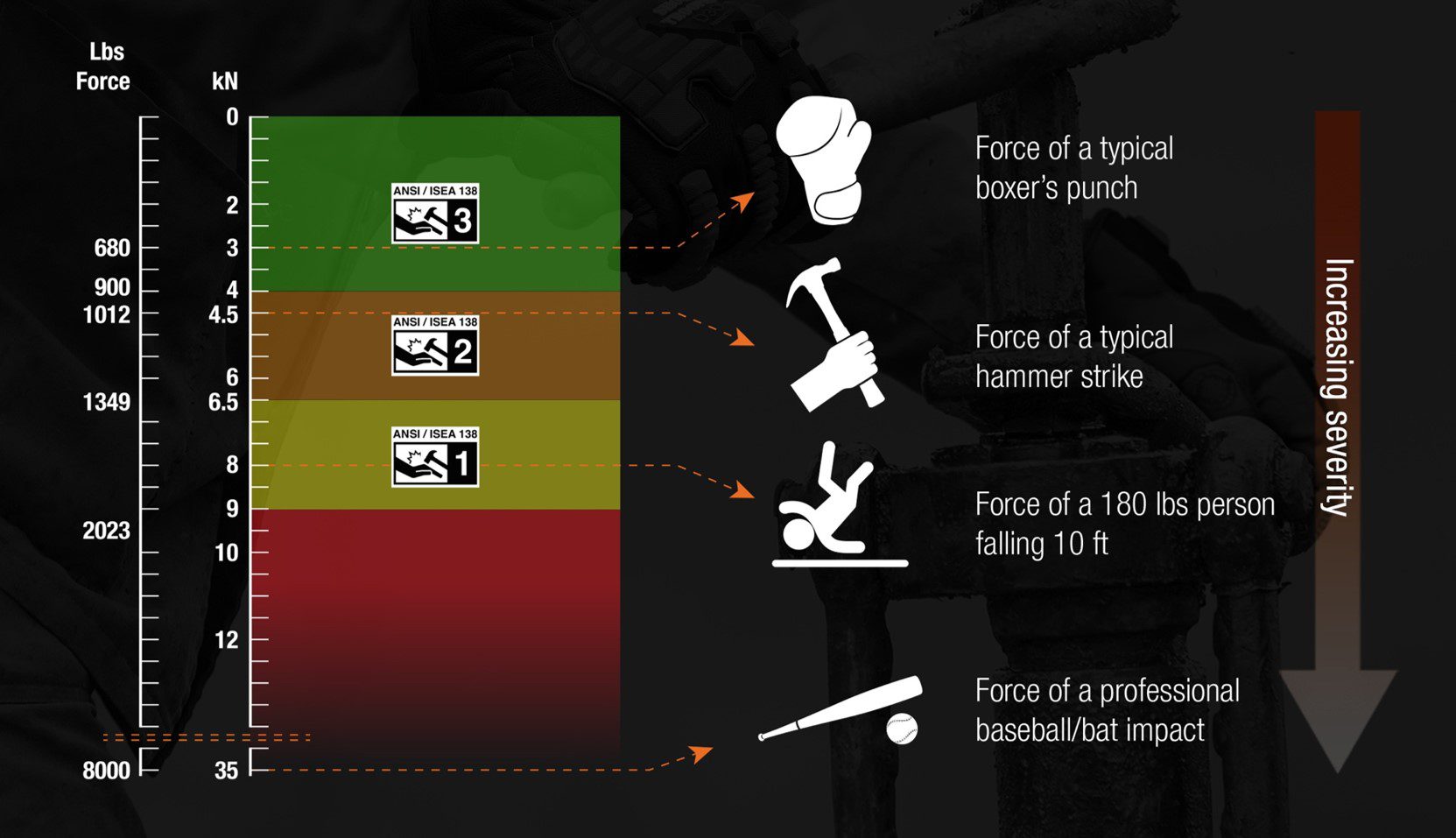

Impact Forces in the Real World

The graphic shown here provides examples of impact scenarios in reference to ANSI/ISEA 138:2019 performance levels. Keep in mind that the contact area and hardness of the materials involved are important to consider when assessing impact in general. And when selecting the most appropriate impact performance level for your job, a hazard assessment needs to be conducted.

At 3 kN, which is in the Level 3 range and about 680 pounds-force, that’s like being punched by a boxer. At about 4.5 kN or about 1,000 pounds-force, that’s like a typical hammer strike on a nail. At about 8.5 kN or about 1,500 pounds-force, that’s like the force of a 180-pound person falling 10 feet. And lastly, the crack you hear when a professional baseball player’s bat makes contact with the ball would be about 35 kN or 8,000 pounds-force.

Getting the Right Impact Protection Glove

When ISEA announced the ANSI/ISEA 138:2019 Impact Standard, our team went out and worked closely with health and safety experts in many industrial fields to better understand what level of impact protection would be needed for the majority of workers in the largest amount of tasks required on the job site. We concluded that for a lot of the major industrial sites, an impact Level 2 glove would be suitable for their application. And since the impact standard has been implemented, many workers have been using our gloves at this current level.

When designing impact protection gloves, we wanted to make sure that we had gloves in every category. In our leather glove category, the 547TPR Van Goat includes full dorsal impact protection on the fingers, top of thumb, knuckles, and also the wrist. The glove also has full-grain goatskin on palm and back and a full sock A5 cut resistant liner. It’s also available in a winter style (9547TPR), as well as a gauntlet version (549TPR) for additional forearm protection.

In the seamless knit category, we have the 357TPR Stealth Dog Fight, which features an A5 cut resistant liner and sandy nitrile palm dip. Similarly, it has full dorsal TPR protection on the back of hand with an Impact Level 2 rating. Within our seamless knit collection, we have impact protection gloves that range in cut resistance levels with 353TPR Stealth Hellcat (A3 cut resistance) and 360TPR Stealth Destroyer (A7 cut resistance).

For Impact Level 3, the 585 Commander uses D3O’s impact additive, which meets the Impact Level 3 rating while lowering the profile in the TPR and maintaining great flexibility and dexterity at the same time. This glove features an oil and water resistant palm and a comfortable spandex back. Also available in a winter style. Additionally, partial proceeds from the sale of this glove go toward the Wounded Warriors foundation.

Another glove under Impact Level 3 is the 5785 Shock Trooper, which is our ultimate in hand protection. It includes full back of hand and top of thumb TPR, which meets the Level 3 rating. It also has water and oil resistance in the treated goatskin leather, a vibration dampening palm, and a full sock A7 cut resistant liner. Also available in a winter style, as well as a gauntlet version. Partial proceeds also go toward the Wounded Warriors foundation.

But Wait There’s More…

We’re continually taking what we learn on the field and job sites and applying it to the gloves we make so that your hands stay protected. As weather gets colder in fall and winter with wetter conditions on the job site, it’s important to find a glove that can protect you from all hazards – 9398TPR Stealth Triple Threat is our first impact protection glove that’s waterproof. That’s right – this double coated glove has a full dip nitrile coating, which provides waterproof resistance, and a sandy nitrile palm dip that helps with grip. It has full back of hand dorsal TPR with an Impact Level 2 rating and an A5 cut resistant liner. Acrylic lining inside helps keep your hands warm throughout your job.

Also to be released later this year is 9456 Hammered. For those working with chemicals, Hammered is a full PVC dipped gauntlet glove with chemical resistance and an EN374-1:2016 protection against six chemicals. It also has dorsal impact protection with an Impact Level 2 rating, a full sock A5 cut resistant liner, and an acrylic liner for warmth, so that you can keep working on your job, no matter the hazards.

ANSI/ISEA 138:2019 is Here to Help Keep Hands Safe

The ANSI/ISEA 138:2019 Impact Standard has proved to be a very powerful and necessary tool in improving hand safety performance since its release. It has filled the gap in impact standards for industrial gloves, as gloves looking to comply under these standards must go through rigorous testing by certified labs. Safety is a high priority for jobs that deal with hazards, and now, impact protection gloves help reduce the risk in impact-related injuries, thanks to the introduction of the new impact standard.

It is important to note that end users should solicit the expertise of a safety professional to assess the appropriate impact performance level for their specific application needs. Although Watson Gloves always aim to make the highest quality in gloves, it is impossible to produce an impact protection glove that meets ALL application needs. It is advised to have a qualified safety professional conduct a hazard assessment to service your needs.

If you’re looking for a handy resource to keep on you, you can download our 1-page summary of the impact standard here. To browse our selection of impact protection gloves, click here.

View all of our webinars, including past ones, such as this one, here.

Sign up for our newsletter!

Stay up to date with the latest Watson Gloves news, releases, and industry updates by signing up to our newsletter!