Watson Webinar Recap: Demystifying Biodegradation and the Circular Economy

Sustainability, biodegradation, the circular economy. What are all these words that circulate our modern vocabulary? And what do they all really mean?

Well, for one, these words are not buzzwords. In fact, these processes have existed in natural habitats since the beginning of time. Now, in current times, with greater consideration from businesses, communities, and humans to be more sustainable, innovative solutions are being made to create products that are more restorative and regenerative to our world, such as biodegradable products, thus completing a circular economy.

This is an incredibly important topic in this time, and we have Rodney Taylor, Watson Gloves’ Director of Sales USA, Paul Wightman, an expert on sustainable plastics, and Christina Yeung, Watson Gloves’ Product Development Manager, to speak on this. Check out a recording of our webinar or read below the recap on demystifying biodegradation and the circular economy.

Sustainable Product Sales & Demand

Sustainable Product Sales

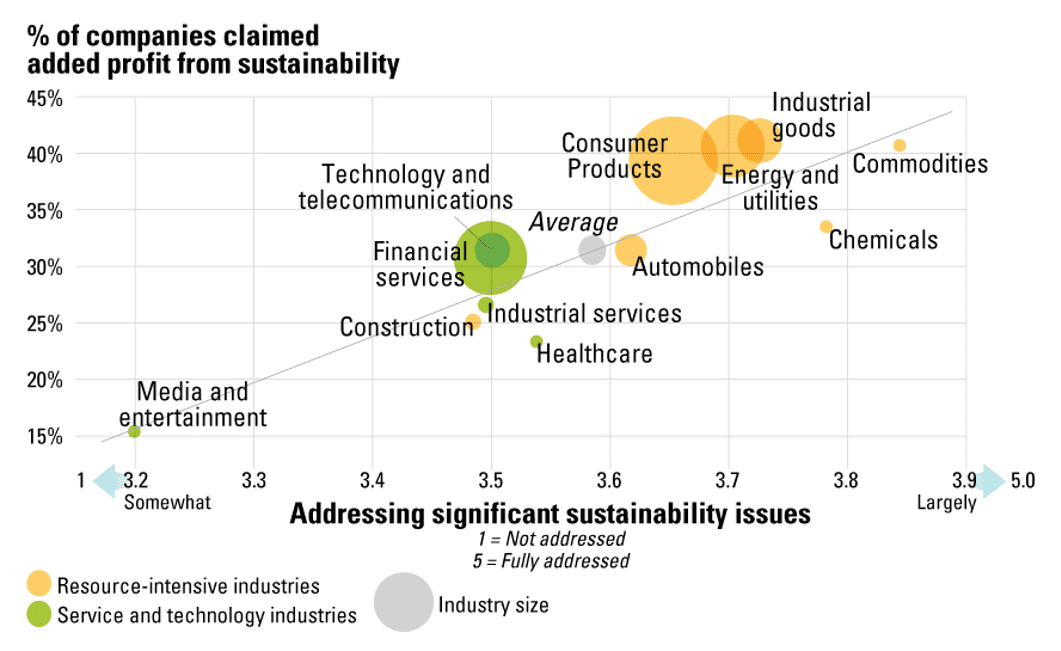

There is clearly an increasing demand for sustainable products. Sustainable product sales have increased by 40% since 2014 – a $43 billion increase. Total sales of sustainable products are expected to pass $150 billion next year. Additionally, we are seeing more executives being held accountable for sustainable initiatives. Today, 65% of senior managers are accountable for sustainable initiatives compared to just 45% back in 2014.

On an industry level, we could see in the chart above that many industries are investing and benefiting from sustainable products and solutions. Consumer products are high up in the chart, but what’s more interesting are the industrial sectors that are focusing on sustainable efforts – that includes industrial goods, energy and utilities, chemicals, and automobiles. As an increasing number of industrial companies bring sustainability actions and goals to greater attention, sustainable PPE offerings can help meet those needs.

Global Rubber Demand

PPE has recently become a household term due to the pandemic. That also means overall PPE usage has increased, which means an increase of PPE waste dumped in landfills. In 2019, 14 million tons of disposable gloves were consumed and the numbers for 2020 we can all imagine will be much higher.

In the US alone, the amount of rubber waste disposal is over 15 billion pounds, and that’s an increase of over 250% in the last 40 years. From a sustainability standpoint, it’s a massive issue, as rubber is a contaminant in current recycling streams. Disposable nitrile gloves are contributing to this non-biodegradable waste in their current form. When nitrile gloves go to landfills, they take hundreds of years to decompose. However, that doesn’t have to be the case.

More research and investments are being put into sustainable options in PPE, such as Watson Gloves’ innovations with biodegradable gloves and gloves made from recycled plastic. As global demand for PPE continues to rise, we expect sustainable PPE to be a long-standing industry trend in the future.

Natural Recycling of Resources

As mentioned in the beginning, the natural world has been continually operating in a circular economy since the dawn of time. There is no waste at any part of the cycle, as everything gets recycled in nature and this continual recycling of resources help support all life (ie. energy, minerals, plants, animals, microbes, water, sunlight, etc.). There’s a lot we humans can learn from the natural environment. That means looking at resources through a different lens to ensure that materials are cycling at the highest level possible.

Biodegradation & the Circular Economy

Biodegradation is the process by which organic substances, meaning carbon-based substances, are broken down into smaller compounds using the enzymes produced by living microbial organisms. And although biodegradation processes vary, the final product is most often carbon dioxide and/or methane, soil and water.

In the US, 85% of the municipal solid waste is being properly discarded and collected residentially. It’s then transferred to biologically active anaerobic waste facilities. These facilities are designed to reduce greenhouse gases and convert carbon-based waste into clean renewable energy.

So in order to achieve circularity, you have to ensure return on value (ROV). What’s important now is finding products that can maximize ROV for the environment.

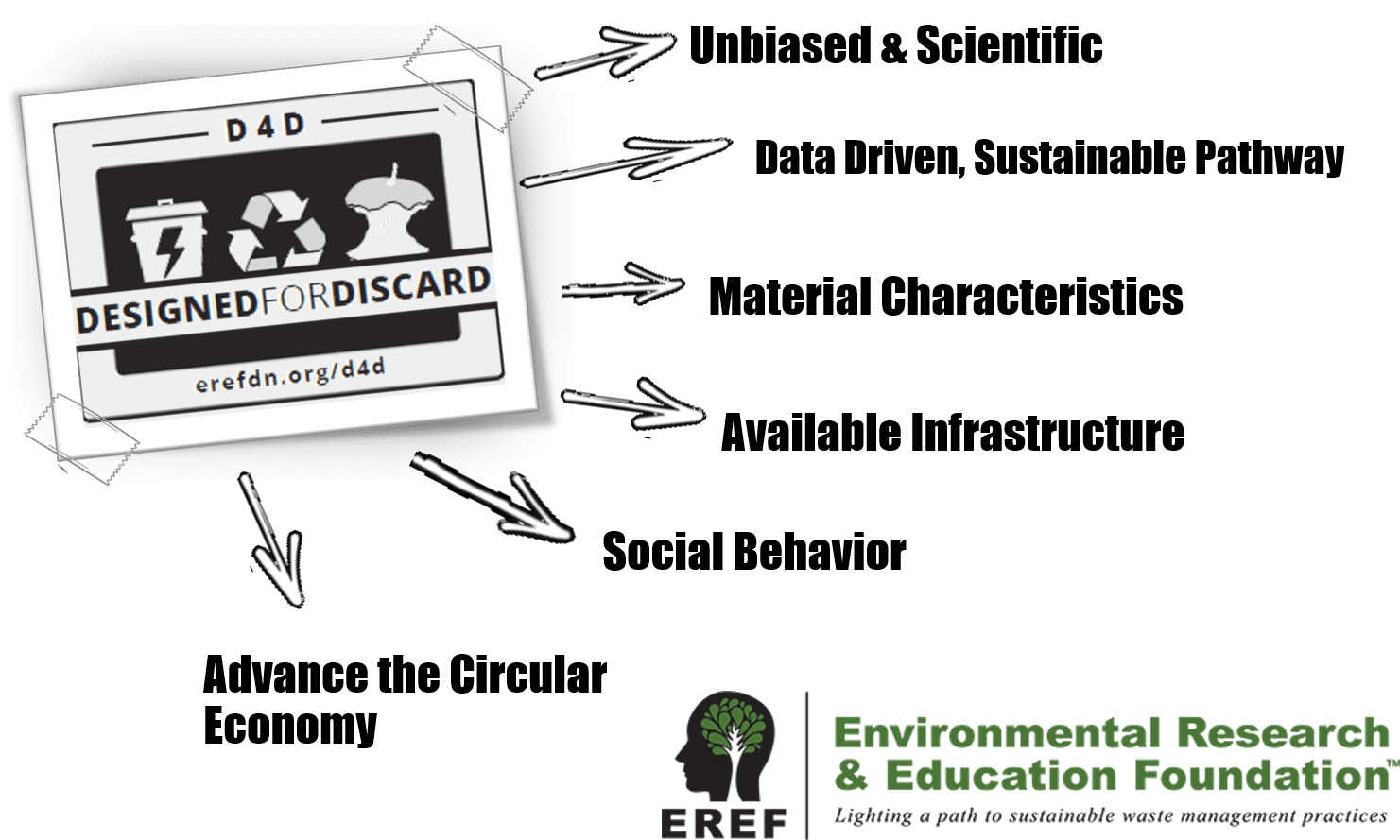

What to Look For – Designed for Discard

Designed for Discard (D4D) is leading the way in thought leadership around sustainable waste. D4D is founded by the Environmental Research & Education Foundation, which aims to provide funding, scientific research, and educational initiatives for waste management practices. D4D’s objective is to take an unbiased, science-based, life cycle assessment of a product. D4D is at the forefront of sustainable waste and if you’re looking to understand more on the topic, they are a good resource to go to.

Three Options for Value in Our Waste Systems

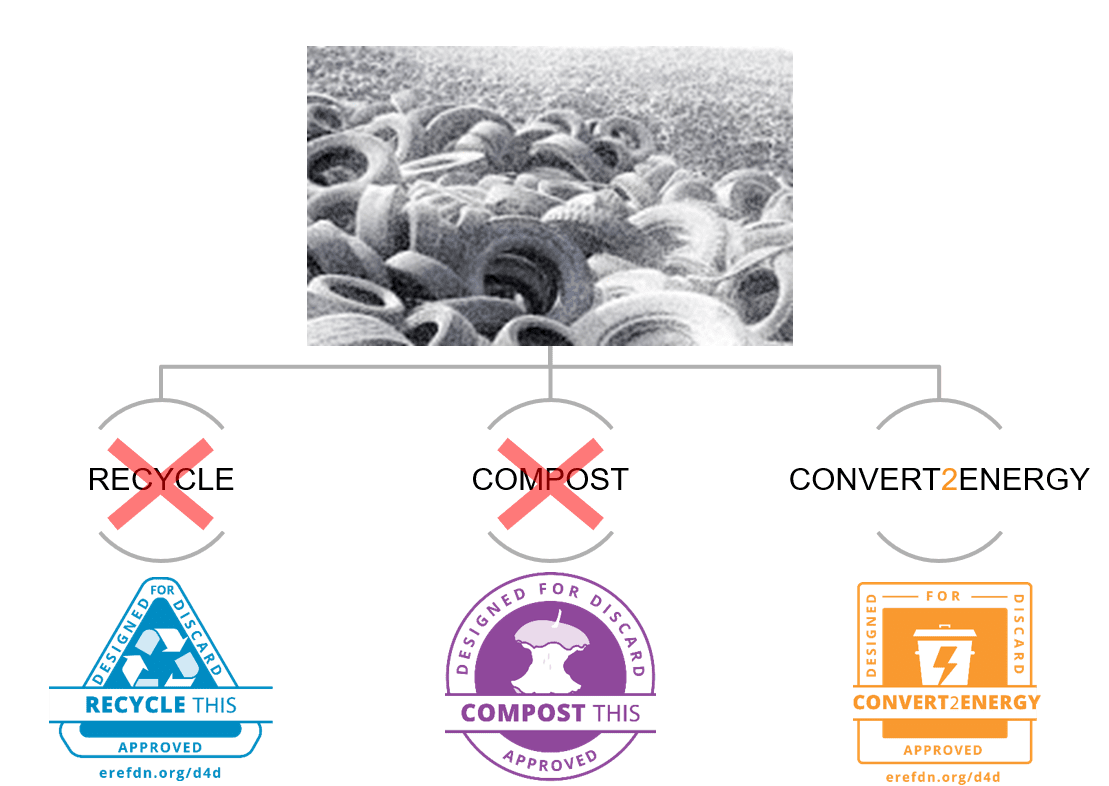

In order to provide a return on value, we have 3 options: 1) recycling, 2) composting, and 3) converting to energy. In regard to rubber management in the waste system, recycling rubber is a contaminant in the recycling stream, so recycling is not an option. Rubber cannot really be composted either. So the only real end of life alternative for rubber is converting to energy. It’s important to note that rubber products are destined for landfills. So bearing in mind the need to maximize ROV for the environment, we have to think about how to handle rubber waste at this point in the value chain (aka at the end of life).

Landfills – What Are They Really?

The science of landfills has increased dramatically. Today’s modern landfills are living, breathing organisms. They’re stringently regulated, strictly managed, and designed to provide anaerobic or low oxygen environments that lead to the production of CH4 (methane). This is important because this methane can be reclaimed as a source of clean, inexpensive energy. In fact, the Clean Air Act requires that all landfills reclaim methane and other greenhouse gases and either burn the gas or use it to create energy.

Reaching Full Circle with the Circular Economy

So this is where it all comes together. If you stop and think about it, we now have a new circular economy for rubber waste. Gloves are worn and disposed after use, then collected and transported to municipal landfills that are designed to generate off gassing of methane as that trash decomposes, and that methane gas can be captured and used to generate clean energy. Given this ability, it’s a no brainer to create biodegradable products so that it can successfully decompose in anaerobic landfills in a short timeframe to produce energy.

What’s important now is the timing of the decomposition. There is an optimal scenario for gloves to break down in a landfill. The conversion to biogas must take no sooner than 2 years but less than 50 years to biodegrade. When a material converts into biogas too quickly, it becomes a greenhouse gas and is wasted. And if it takes too long to degrade, then it is also wasted because it cannot be harnessed by smart landfills. Thus, although it’s clear that a long degradation time will not fulfill any ROV, a faster degradation is actually NOT better, as there is an optimal timeframe.

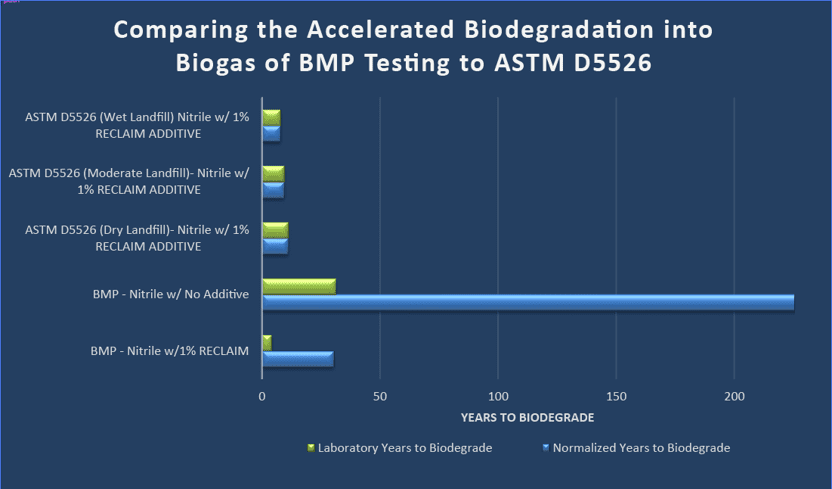

Regular Nitrile Gloves vs. Nitrile Gloves Using Reclaim™ Additive

The chart above shows how long it takes for a nitrile glove to degrade into biogas under various conditions. It illustrates clearly, especially in the blue bars, that any gloves that do not have Reclaim™ additive can take up to 200+ years to biodegrade. Whereas even 1% of the Reclaim™ additive in the polymer can greatly reduce the time a glove takes to biodegrade in the landfill ranging from 8 to 11 years. That’s why the Reclaim™ decomposition additive used in Watson Gloves’ Green Monkey gloves is critically important and represents a powerful market innovation – more on that later.

As a side note, as can be seen here, there are variance in biodegradation, as landfills can vary on their geographical environment. Wetter environments will create more moisture and thus create a higher microbial process, which leads to a faster biodegradation time compared to dry environments. But as long as biodegradation is happening within modern landfill conditions, then ROV is captured within the 8-11 year timeframe, which is the most important part.

Biodegradation Testing

As you could see from the chart, it references “ASTM D5526.” What does that mean? It’s one of the two test standards for landfill biodegradation by the American Society for Testing and Materials (ASTM). They are a reputable test method developer and have created technical standards for a wide range of products, such as biodegradation testing.

The ASTM D5511 test is designed to provide quick results in an anaerobic environment. It validates whether a material can convert to biogas in low heat, low moisture, high pressure, no light, and limited oxygen environments. The ASTM D5526 test is a more stringent, longer term test in an anaerobic environment. The results are slower than ASTM D5511 but more accurate to the landfill performance. ASTM D5526 testing is very expensive, and suppliers have to balance the value of the performance claim versus the high cost of testing.

It is extremely important to cite and use test methods from established and reputable test providers, such as ASTM. Having credible test method development organizations do such tests is necessary to provide a set of objective standards to measure products by. Without them, suppliers can make claims based on their own standards and test methods, which are much more questionable.

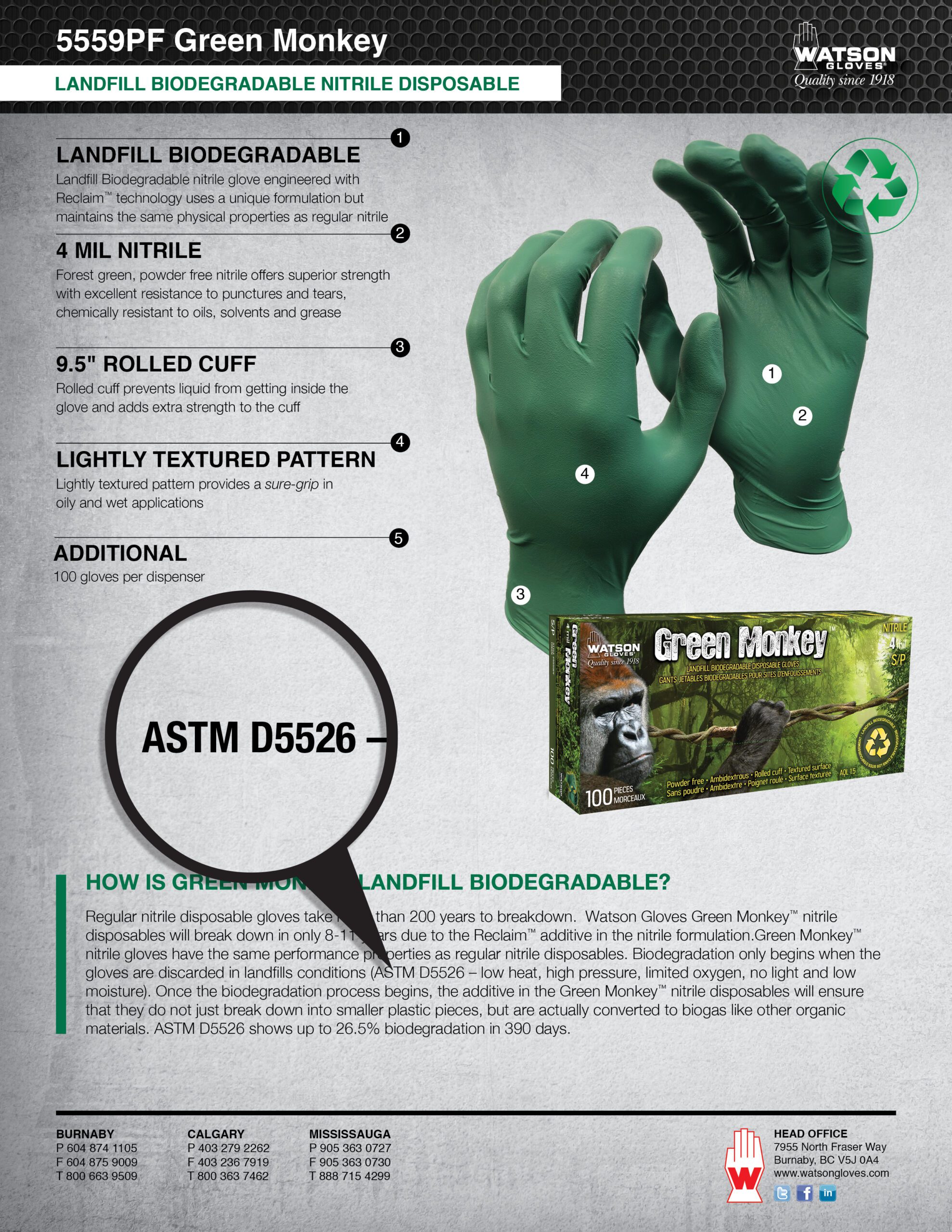

5559PF Green Monkey ASTM D5526 certified and tested

Design with Innovation & Purpose – Welcome the New Reclaim™ Additive

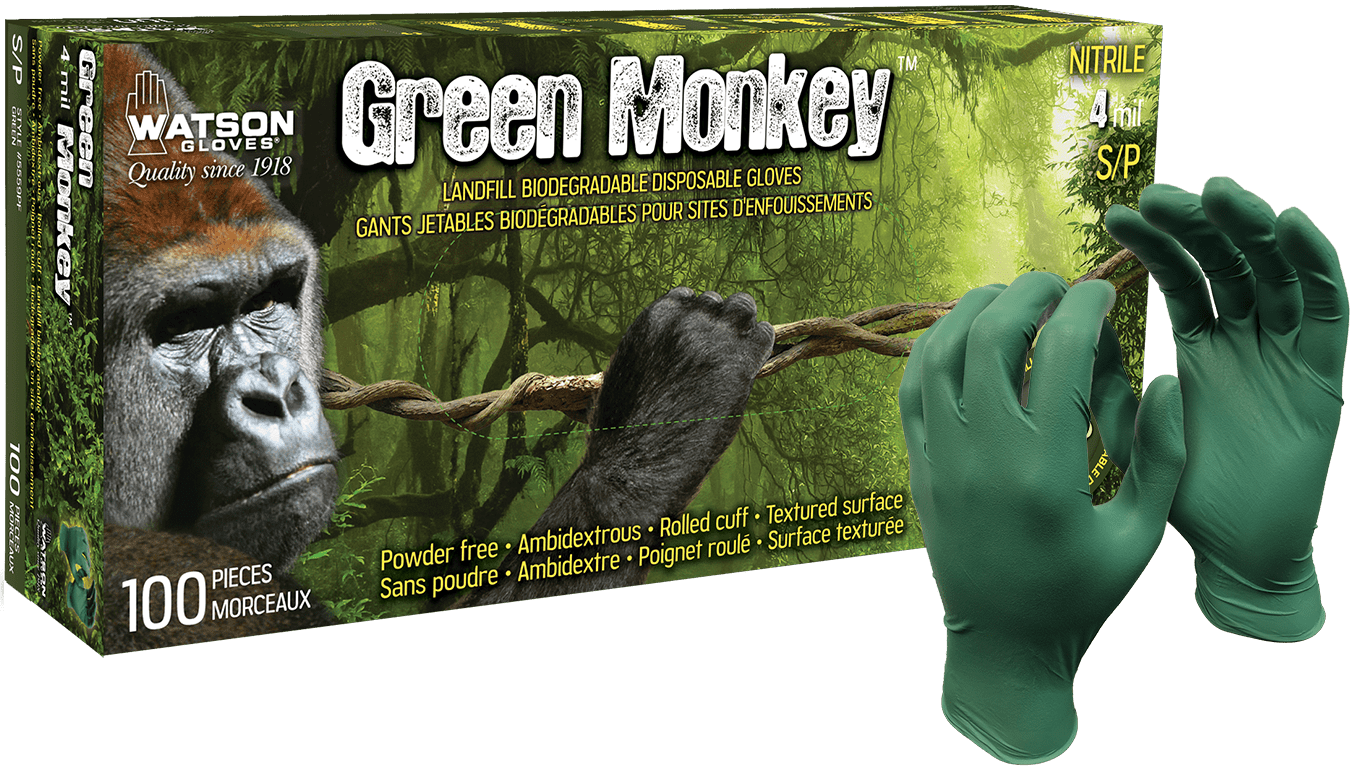

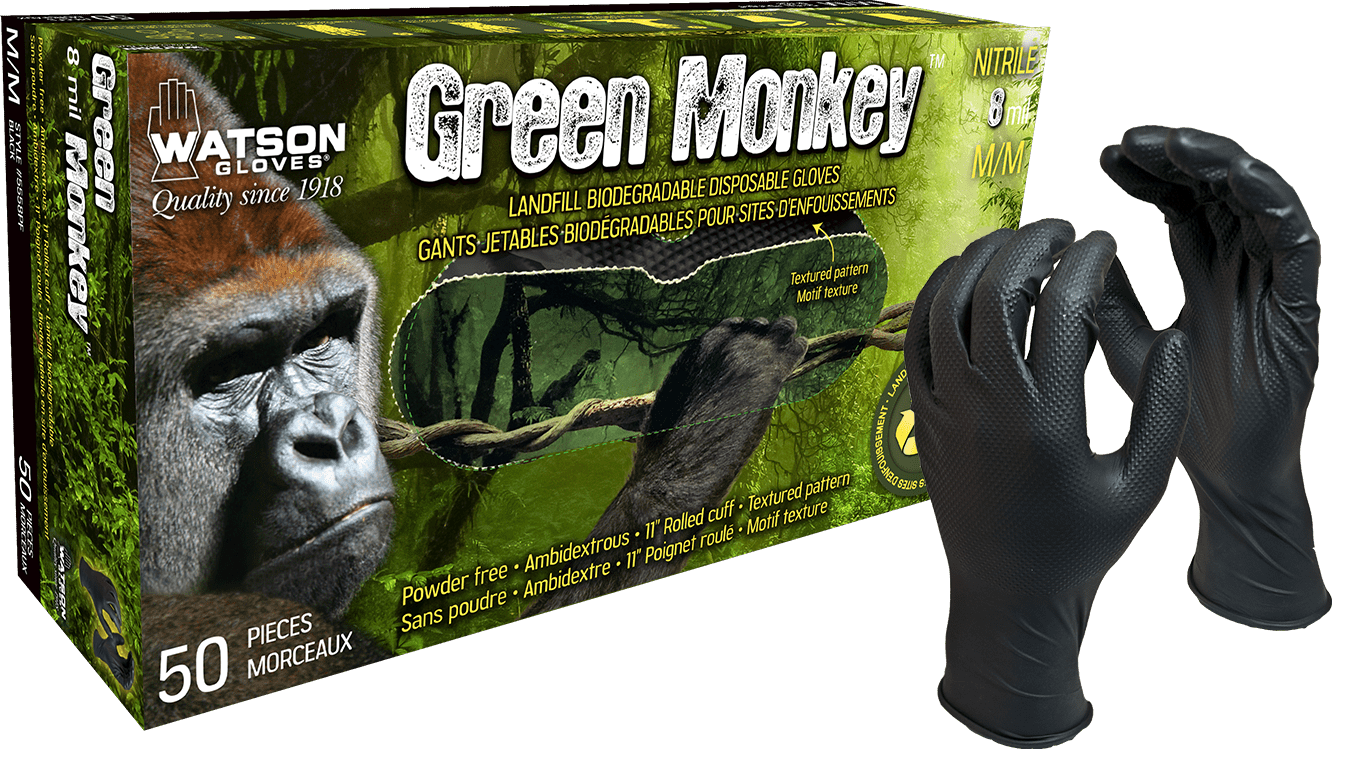

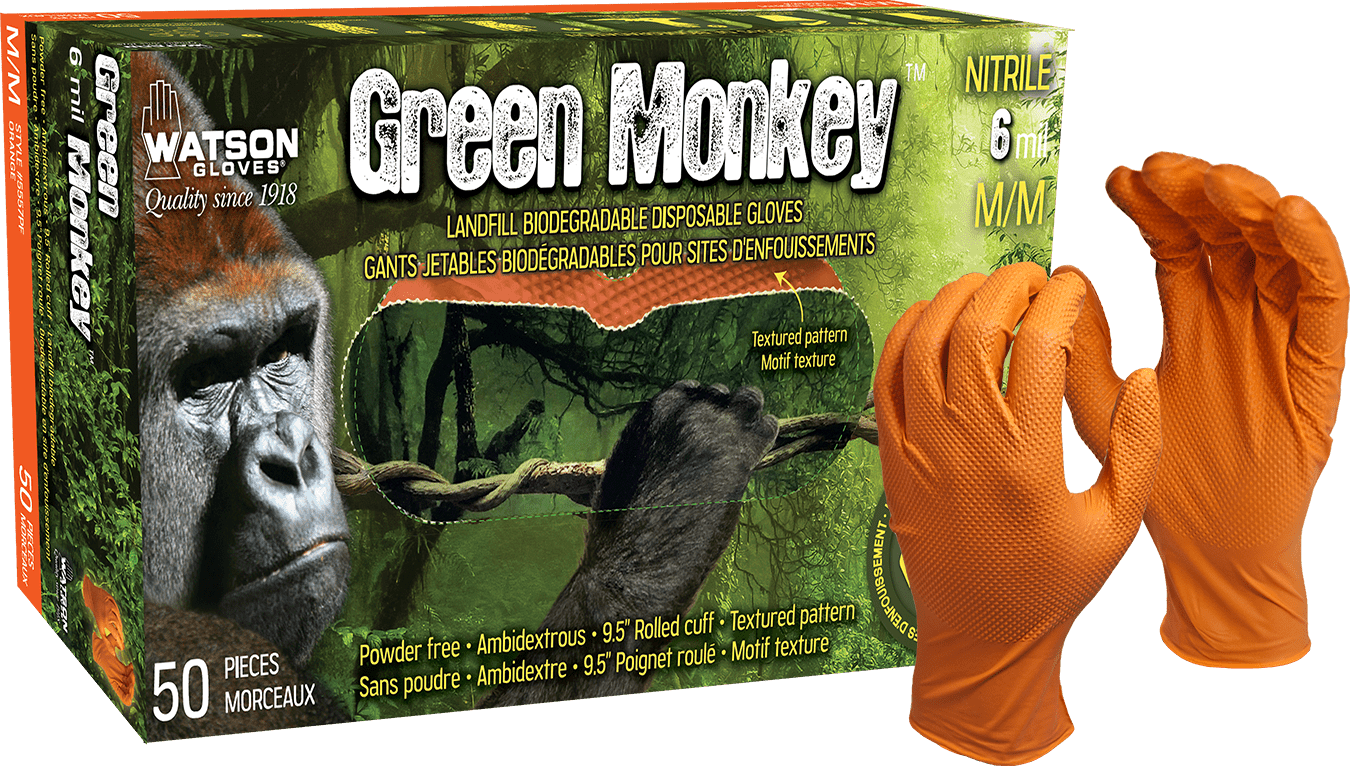

One of the main drivers for innovation at Watson Gloves is to bring new products to market with a focus on sustainability. We continue to grow our line of products that focus on the end of life (biodegradability), which completes the circular economy Our much popular Green Monkey brand was introduced in 2019 with the 4 mil 5559PF Green Monkey first to come out. Now, we’ve expanded the line with the new 6 mil 5557PF Green Monkey and 8 mil 5558PF Green Monkey, offering you a greater choice in biodegradable disposable gloves for your job.

These gloves feature the Reclaim™ addictive, which enhances the biodegradation in landfill conditions. And when compared to regular nitrile gloves, the Green Monkey gloves biodegrade in 8 years compared to 200+ years for a regular nitrile glove. And ASTM D5526 tests for our Green Monkey gloves show up to 26.5% biodegradation in 390 days.

It’s important to note that the performance and shelf life of these gloves are not affected in any way by the Reclaim™ addictive. There is no requirement for the user to change their behaviour when they are using these gloves. The only thing you need to do to activate its biodegradation activities is to dispose them properly so that they can end up in a landfill. Once in landfill conditions, the Reclaim™ additive is activated to attract microbes that break down the glove into biogas, which is then turned into energy!

You can check out our Green Monkey brand video here.

Along with expanding our Green Monkey line, we’re also extremely excited in expanding our biodegradable options beyond disposable gloves. That’s right. Coming in spring 2021, we will have fully biodegradable seamless knit gloves. These gloves utilize biodegradable yarn called ZeroWaste™ to degrade as quickly as five years compared to the 50+ years a typical glove made from synthetic material would take.

Two biodegradable seamless knit gloves will be released next spring. The 319 Stealth Zero comprises of 15gg ZeroWaste™ biodegradable nylon yarn. It has a foam nitrile palm that also has Reclaim™ additive for enhanced biodegradability, while being excellent in wet and oily conditions. We also have the 329 Jade, which also feature 15gg ZeroWaste™ biodegradable nylon yarn and foam nitrile coating with Reclaim™ additive. And when you put on these gloves, you’ll feel incredible comfort and breathability without any compromise in performance.

This is a huge breakthrough for Watson Gloves, and we’re very excited to open up our offering of biodegradable gloves. These will be our very first biodegradable non-disposable gloves released into the market and our goal is to continue innovating and expanding our line of biodegradable products.

319 Stealth Zero

Coming Soon

329 Jade

Coming Soon

Gloves to Energy? Better Believe It!

As sustainability continues to play a role in the actions we take as individuals and businesses, it’s important to think about how we can reach our sustainability goals. If you’re in the industrial market, you’re very much likely using PPE. And no doubt, with the minimal amount of sustainable PPE choices, there is a lot of PPE waste that is harming our environment long-term. It doesn’t have to be like that, however.

At Watson Gloves, we’re continually expanding our lines of sustainable products, such as WasteNot™ gloves and Reclaim™ gloves. The powerful technology of Reclaim™ additive is a gamechanger in our products, as the additive provides enhanced biodegradation to the gloves once they’re in landfill conditions without compromising the performance and shelf life of the gloves. And when the biodegradation process is complete in landfills, biogas from the gloves turn into energy that our homes, businesses, and communities use.

The future is here at Watson Gloves, and we’re eager to be at the forefront of sustainable innovations in the PPE industry, as we continue to push more biodegradable products into the market. We can’t wait for you to join us in reducing PPE wastage and restoring our environments with more energy.

View all of our webinars, including past ones, such as this one, here.

Sign up for our newsletter!

Stay up to date with the latest Watson Gloves news, releases, and industry updates by signing up to our newsletter!