How to Choose the Right Cut-Resistant Glove

What are Cut-Resistant Gloves?

Cut-resistant gloves are designed to help protect hands from lacerations and puncture caused by sharp objects such as blades, glass, sheet metal, or wire.

When it comes to hand protection, choosing the right cut-resistant glove isn’t just about safety – it’s about performance, comfort, and compliance on the job site. Whether you’re working in manufacturing, construction or handling sharp materials, here is a step-by-step guide to help you find the right glove for the job. We will walk you through the 8 steps on “how to choose the right cut-resistant glove”.

***It is important to keep in mind that hand protection is the last line of defense and no gloves are “cut proof” but high-quality cut-resistant gloves can significantly reduce the chance of injury. Watson Gloves warns all potential users of its cut-resistant products that they are not suitable for all uses. Please discuss with your Occupational Health and Safety Officer regarding other hazards on site.

The 8 Steps to Choosing the Right Cut-Resistant Glove

Step 1: Complete a Hazard Assessment

Before selecting a glove, conduct a thorough risk assessment of your worksite. Identify all potential hazards beyond just cuts:

- Cut hazards: glass shards, sheet metal, blades, wires.

- Puncture risks: nails, splinters, sharp tools.

- Chemical exposure: solvents, oils, cleaning agents.

- Liquid penetration: water, oils, or other fluids.

- Crush hazards: heavy equipment, pinch points.

Understanding the full scope of hazards helps determine whether you need multi-protection gloves with features like impact resistance, water-resistant barriers, or chemical-resistant coatings.

Did you know that Watson Gloves provides a no cost, no obligation on-site audit called a S.W.A.T?

Step 2: Determine Your Application

The nature of the task dictates the glove’s construction and level of cut-resistance needed:

- Light assembly tasks: Require thin, flexible gloves with moderate cut-resistance and high dexterity.

- Heavy-duty operations: Demand reinforced gloves with high cut-resistance, impact protection, and possibly insulation or waterproofing.

For example:

Construction & Utilities

In construction and utility sectors, gloves must withstand rugged conditions and provide protection from both cuts and environmental hazards:

- General construction: Gloves with ANSI/ISEA Cut Level A4–A6 are common for handling sharp building materials

- Utilities: Workers benefit from gloves that combine cut resistance with impact protection and water resistance, especially in outdoor or winter conditions

Industrial & Manufacturing

Cut-resistant gloves are widely used in manufacturing environments where workers handle sharp tools, sheet metal, or glass. These include:

- Metal fabrication and machining: Gloves with high tensile strength fibers like Kevlar® and P-aramid are ideal for resisting sharp metal edges

- Glass handling: Requires gloves with excellent grip and high cut resistance to help prevent injuries from broken or sharp glass

- Automotive assembly: Workers often need gloves that balance dexterity with protection from sharp components

Oil and Gas /

Welding

Specialized gloves are designed for high-risk environments like oil rigs and welding stations:

- Oil & Gas: Gloves must resist oil penetration, offer high durability, and often include cut-resistant liners (e.g. CutShield™)

- Welding: Gloves for MIG, TIG, and Stick welding often include Kevlar® thread and leather exteriors, with some models incorporating cut-resistant liners for added safety

Step 3: Choose the Cut-Resistant Level Needed

The ANSI/ISEA 105 is a North American standard that provides a consistent framework for evaluating the performance of hand protection products. The EU has an equivalent standard, EN 388:2016, however for the purpose of this blog post, we will focus on ANSI/ISEA 105.

ANSI/ISEA 105 covers various protective properties, including:

- Cut resistance

- Puncture resistance

- Abrasion resistance

ANSI/ISEA 105 Cut Levels vs EN 388 Ratings

- ANSI Levels A1–A9: A1 is minimal protection; A9 is maximum.

- EN 388 Ratings: Use numbers and letters to indicate cut, tear, puncture, and abrasion resistance.

On the image below you can see how ANSI and EN 388 correlate.

For cut-resistance specifically, the standard uses a nine-level scale (A1 to A9) based on the amount of force (in grams) required for a blade to cut through the glove material using a standardized test method (ASTM F2992-15) in lab conditions. Cut levels are shown below: in detail with suggested applications ranging from extreme to low hazards.

View all of our cut-resistant gloves in each ANSI/ISEA 105 cut level:

View all of our cut-resistant gloves in each EN 388 rating:

Step 4: Choose Types of Materials Used

Factors affecting cut-resistance include:

- Yarn strength: Aramid and HPPE offer high tensile strength, Aramid is also good for heat protection.

- Hardness: Stainless steel or glass fibers increase resistance.

- Lubricity: Slippery yarns like HPPE allow blades to slide over.

- Knit construction: Rolling action of yarns helps deflect cuts.

It is important to understand the many materials that are used to manufacture a cut-resistant glove. These gloves are made from high-performance materials such as:

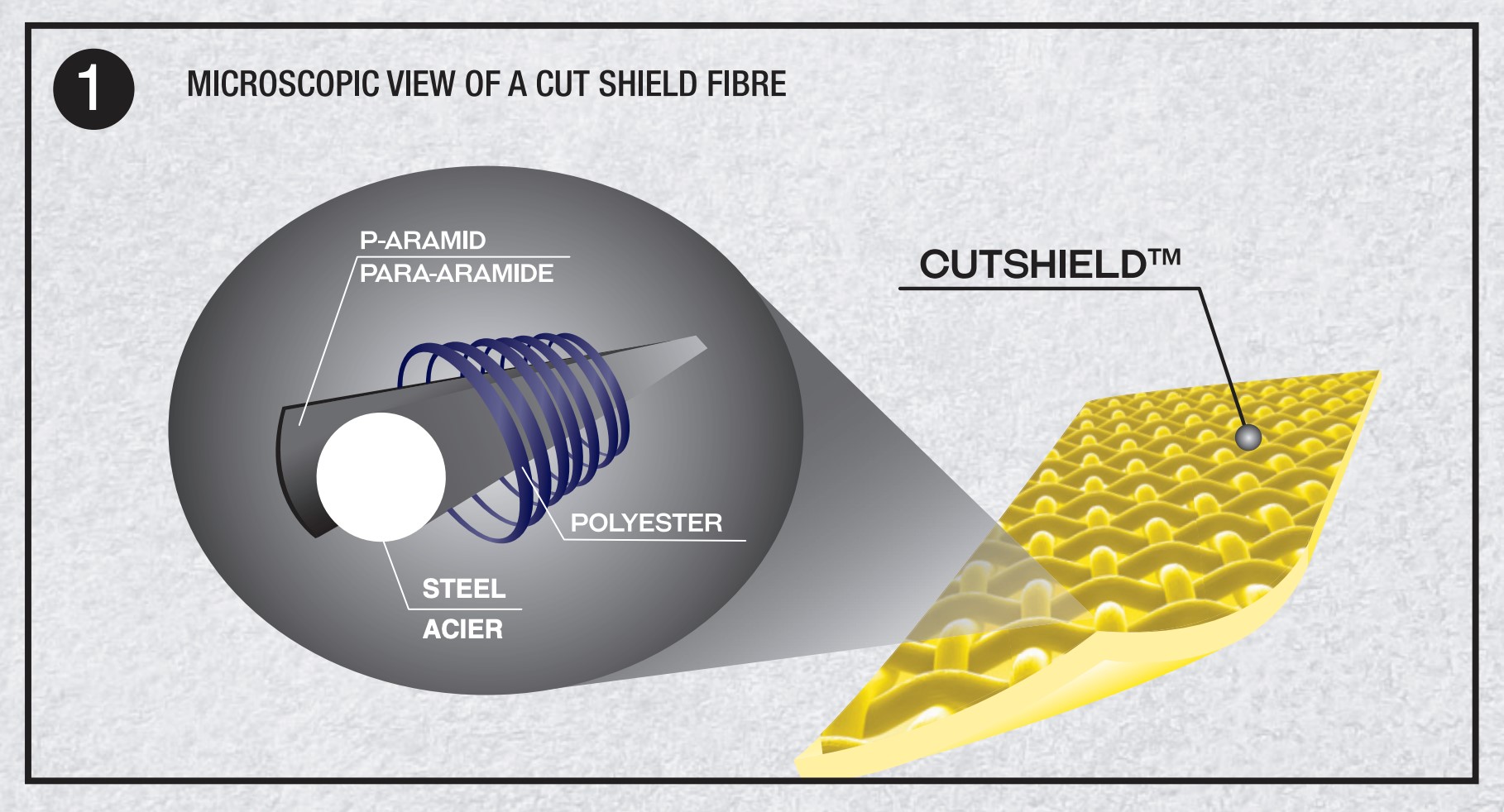

- Cutshield™ – a cut resistant Full sock 360 degree liner made from a blend of P-aramid, steel and polyester fibers. These liners are found in our high performance cut gloves.

- Kevlar® or P-aramid – known for its strength and heat resistance.

- HPPE (High-Performance Polyethylene) – offers excellent cut resistance and comfort.

- Steel mesh or wire – used in high-risk environments like meat processing.

- Glass fibers – used to reinforce the yarn, provides the lowest cut resistance – generally from A2 to about A4. Gloves containing glass can help dull a blade that slides across glove.

- Steel fibers – used to reinforce the yarn, steel provides higher cut resistance than glass – A5-A9, but is the heaviest core material and also the most stiff and rigid.

The level of protection varies depending on the glove’s material, construction, and intended use.

Other materials can also be used in cut-resistant gloves like nylon and polyester to wrap around the cut fibres (glass and steel). See below for a graphic illustrating our CutShield™ full sock liner with polyester wrapping around the steel fibres for additional comfort.

At Watson Gloves, many of our cut-resistant gloves are made from recycled plastic bottles (rPET) instead of virgin polyester. These gloves, made with our recycled WasteNot™ yarn, divert on average one 500ml plastic bottle from landfills. Click here for WasteNot™ cut-resistant gloves.

Additional Features:

Do you need additional hazard protection features like impact protection or chemical resistance?

Step 5: Determine How Much Dexterity is Needed

Do you need tactile sensitivity for precision tasks like inspection or small parts handling? Opt for:

- High-gauge liners (e.g., 18gg) for thinner, more dexterous gloves. The higher the gauge, the thinner the liner.

- Ergonomic thumb designs like keystone or wing thumbs for better movement.

- Snug fit to reduce fatigue and improve control.

Stealth Seamless Knits – All Purpose Cut-Resistant Gloves

The Stealth brand of seamless knit gloves offers a second skin fit and maximum dexterity for all types of working conditions. Our gloves come in a variety of coatings to provide Slip Defense against dry, oily and wet conditions. The Stealth brand also offers a range of cut-resistant gloves with varying degrees of Cut Defense against blade cuts or rough edges. If you’re looking for work gloves with high dexterity, excellent grip, and comfort, then Stealth is the brand for you.

Step 6: Determine How Much Grip is Needed

Grip is essential when working with slippery surfaces or oily materials. Choose coatings based on your environment:

- Latex: Excellent dry and wet grip, poor for oily conditions.

- Nitrile: Great for oily and chemical environments, available in finishes like sandy or microfoam.

- Polyurethane (PU): Lightweight, breathable, and ideal for high dexterity tasks with good grip across conditions.

Step 7: Do You Need More Protection Against The Elements?

Consider the climate and exposure:

- Cold environments: Look for insulated liners (e.g., acrylic or Thinsulate™) and knit wrists to retain warmth.

- Hot conditions: Breathable materials and coatings that wick moisture.

- Wet or windy settings: Water resistant barriers and full-dip coatings for maximum protection.

3M Recycled Thinsulate™

We saw an opportunity to elevate the industrial PPE industry and be a market innovator by using recycled materials in winter glove lining. Industrial workers can go through numerous pairs of gloves each year due to rugged daily use, and the used products end up in landfills. In collaboration with 3M, Watson Gloves now includes Recycled Thinsulate™ lining in many winter styles, bringing sustainability to the job site without compromising warmth or performance.

Hy+Dry® Barrier

Hy+Dry® is a breathable barrier designed with advanced technology, providing ultimate protection from wind and water. Keeping your hands warm, dry, and comfortable.

Step 8: Determine Sizes Needed

Fit matters! It is more than comfort—it’s about safety and efficiency.

Gloves should:

- Match hand size and shape

- Allow natural movement without excess bulk

We have cut-resistant gloves for all hand sizes. Poor fit can compromise safety and performance, so sizing is critical. Need help to determine your size? Use our sizing chart (charts for both men and women).

Choosing the right cut-resistant glove involves balancing protection, dexterity, grip, environmental adaptability, and sustainability. By following these steps, you ensure your team is equipped with gloves that not only meet safety standards, but also enhance performance and comfort.

Have more questions? Reach out to our Hand Protection Specialists for more information.

Loading ...

Loading ...