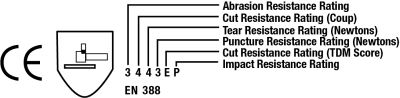

EN 388 Mechanical Hazards

Abrasion Resistance

Based on the number of cycles required to abrade through the sample glove (abrasion by sandpaper under a stipulated pressure). The protection factor is then indicated on a scale from 1 to 4 depending on how many revolutions are required to make a hole in the material. The higher the number, the better the glove.

Blade Cut Resistance (Coup Test)

Based on the number of cycles required to cut through the sample at a constant speed. The protection factor is then indicated on a scale from 1 to 5.

Tear Resistance

Based on the amount of force required to tear the sample.

The protection factor is then indicated on a scale from 1 to 4.

Puncture Resistance

Based on the amount of force required to pierce the sample with a standard sized point. The protection factor is then indicated on a scale from 1 to 4.

Blade Cut Resistance (TDM Test ISO 13997)

The TDM-100 machine requires a copper filament to be placed between the mounting tape and test fabric so that once the sample fabric is cut through and the blade touches the copper filament, the cut resistance rating is measured, thus yielding a more accurate cut resistance rating. The ISO 13997 rating will be measured in Newtons. The protection factor is then indicated on a scale from A to F. The European Norm (EN) 388 standard is in the revision process and will be released in early 2016.

Impact Resistance

Impact is tested on the knuckle bar only. The protection factor is indicated as a P (Pass) or F (Fail)

Click the button below to find the right EN388 compliant gloves for your job.

Sign up for our newsletter!

Stay up to date with the latest Watson Gloves news, releases, and industry updates by signing up to our newsletter!