How to Choose the Right Leather Glove

Navigating the realm of leather gloves to find the perfect pair for your job might seem like a daunting task, we aim to make it straightforward and effortless.

Choosing the right leather glove requires understanding the nature of your work and the potential hazards involved. Whether it’s cut, heat, impact, oil, puncture, water, or varying weather conditions, being prepared is essential. Our range spans gloves designed for welding, high-performance tasks, utility work, casual wear, and the cold of winter. At Watson Gloves, our commitment is to ensure a perfect fit for every hand and task. Let’s find your ideal pair together.

The Five Different Steps to Choosing a Leather Work Glove

Choose Your Leather Type

Selecting the right leather type means understanding each hide’s distinct characteristics and how they suit various applications.

Why Choose Goatskin Leather?

Goatskin tops the charts in durability. Goatskin gloves are extremely supple and abrasion-resistant, thanks to the natural lanolin. Goatskin without extra liners can provide excellent dexterity.

Why Choose Goatskin Leather?

Goatskin tops the charts in durability. Goatskin gloves are extremely supple and abrasion-resistant, thanks to the natural lanolin. Goatskin without extra liners can provide excellent dexterity.

Why Choose Cowhide Leather?

The most popular leather for gloves, cowhide, is well-loved for its perfect blend of comfort and durability. Its excellent abrasion resistance makes it ideal for the toughest tasks.

Why Choose Cowhide Leather?

The most popular leather for gloves, cowhide, is well-loved for its perfect blend of comfort and durability. Its excellent abrasion resistance makes it ideal for the toughest tasks.

Why Choose Deerskin Leather?

Deerskin is known for its ultra-comfort and suppleness. Deerskin is hard-wearing and more flexible than cowhide while also offering more warmth, making it perfect for all-season gloves.

Why Choose Deerskin Leather?

Deerskin is known for its ultra-comfort and suppleness. Deerskin is hard-wearing and more flexible than cowhide while also offering more warmth, making it perfect for all-season gloves.

Why Choose Pigskin Leather?

Pigskin’s standout feature is its breathability. It withstands moisture without stiffening, getting softer with each use.

Why Choose Pigskin Leather?

Pigskin’s standout feature is its breathability. It withstands moisture without stiffening, getting softer with each use.

Split or Full-Grain?

*Leather Grading: Is set up on a universal scale. A hide is divided into three grades, A,B,C. A=TOP grade and is softer with few surface flaws.

Why Choose Full Grain Leather?

This is the outer, smoother surface of the hide, promising superior wear resistance compared to split.

Why Choose Full Grain Leather?

This is the outer, smoother surface of the hide, promising superior wear resistance compared to split.

Why Choose Split Leather?

Sourced from the hide’s underside, suede or split leather, though stiffer than full-grain, provides a more cost-effective alternative. It stands out with remarkable abrasion resistance and a natural ability to repel water, attributed to the density of its fibers. Additionally, split leather’s inherent heat resistant qualities make it a popular choice for welding gloves.

Why Choose Split Leather?

Sourced from the hide’s underside, suede or split leather, though stiffer than full-grain, provides a more cost-effective alternative. It stands out with remarkable abrasion resistance and a natural ability to repel water, attributed to the density of its fibers. Additionally, split leather’s inherent heat resistant qualities make it a popular choice for welding gloves.

Choose a Pattern

The way a glove is cut helps determine the dexterity and comfort. There are two basic patterns used for cutting gloves.

Why Choose Gunn Cut?

Designed with precision in mind, gunn cut gloves showcase a single-piece, seamless back, keeping the fine seams clear of the palm’s work-intensive area. The independent sewing of the two central fingers into the palm reduces excess material, enhancing your dexterity for effortless tool handling. This meticulous design promotes extended wear and optimal comfort, reducing strain on the glove, while providing a natural grip for everyday tasks.

Why Choose Gunn Cut?

Designed with precision in mind, gunn cut gloves showcase a single-piece, seamless back, keeping the fine seams clear of the palm’s work-intensive area. The independent sewing of the two central fingers into the palm reduces excess material, enhancing your dexterity for effortless tool handling. This meticulous design promotes extended wear and optimal comfort, reducing strain on the glove, while providing a natural grip for everyday tasks.

Why Choose Clute Cut?

Featuring a one-piece palm and a straight thumb, clute cut gloves are crafted without a seam at the base of the fingers, instead placing seams along the inner side of each digit. This design approach offers a generous, comfortable fit, making these gloves an economical choice without compromising on the quality.

Why Choose Clute Cut?

Featuring a one-piece palm and a straight thumb, clute cut gloves are crafted without a seam at the base of the fingers, instead placing seams along the inner side of each digit. This design approach offers a generous, comfortable fit, making these gloves an economical choice without compromising on the quality.

Choose a Thumb

The design of a glove’s thumb might seem like a minor detail, but it plays a significant role in the glove’s overall functionality and comfort. While there’s no one-size-fits-all answer, the best thumb design ultimately depends on the user’s preference and what feels most comfortable for them.

Why Choose an Inset Thumb?

Crafted as an individual piece and sewn into the glove, inset thumb gloves offer greater comfort and dexterity. Reinforced with extra stitching, it’s optimally positioned to mirror the natural movement of your hand, all the while increasing the longevity of the glove.

Why Choose an Inset Thumb?

Crafted as an individual piece and sewn into the glove, inset thumb gloves offer greater comfort and dexterity. Reinforced with extra stitching, it’s optimally positioned to mirror the natural movement of your hand, all the while increasing the longevity of the glove.

Why Choose a Wing Thumb?

Crafted with an intentionally angled construction that continues across the palm for improved comfort. With less stitching in the crotch of the thumb, wing thumb gloves enhance flexibility and less hand fatigue.

Why Choose a Wing Thumb?

Crafted with an intentionally angled construction that continues across the palm for improved comfort. With less stitching in the crotch of the thumb, wing thumb gloves enhance flexibility and less hand fatigue.

Why Choose a Straight Thumb?

Crafted for tasks that require less strenuous activity, straight thumb gloves prioritize affordability and simplicity. Although they may not provide the full range of thumb motion, their minimalistic design and reduced stitching making them the most price conscious choice.

Why Choose a Straight Thumb?

Crafted for tasks that require less strenuous activity, straight thumb gloves prioritize affordability and simplicity. Although they may not provide the full range of thumb motion, their minimalistic design and reduced stitching making them the most price conscious choice.

Choose a Cuff Style

The choice in your glove cuff depends greatly on your application; for example: welding may require extended forearm protection, while power tool may require easy removal in case of an emergency.

Why Choose a Shirred Elastic Wrist?

Outfitted with an elastic wrist, these gloves gather leather at the wrist, ensuring a snug and secure fit to keep out dirt and debris. This feature is often seen in conjunction with our safety cuffs.

Why Choose a Shirred Elastic Wrist?

Outfitted with an elastic wrist, these gloves gather leather at the wrist, ensuring a snug and secure fit to keep out dirt and debris. This feature is often seen in conjunction with our safety cuffs.

Why Choose a Slip-on Cuff?

A glove design that seamlessly extends beyond the wrist, eliminating the need for a separate cuff. This ensures a smooth transition and facilitates quick and easy on/off.

Why Choose a Slip-on Cuff?

A glove design that seamlessly extends beyond the wrist, eliminating the need for a separate cuff. This ensures a smooth transition and facilitates quick and easy on/off.

Why Choose a Safety Cuff?

Built with durability and quick on-and-off in mind, safety cuffs feature a bonded material band that extends beyond the wrist. This design offers additional coverage and ensures the gloves can be swiftly removed when required, providing a balance of protection and convenience.

Why Choose a Safety Cuff?

Built with durability and quick on-and-off in mind, safety cuffs feature a bonded material band that extends beyond the wrist. This design offers additional coverage and ensures the gloves can be swiftly removed when required, providing a balance of protection and convenience.

Why Choose a Velcro Closure?

Gloves with Velcro closures feature a strap that wraps around the wrist, pulling the two halves together. This design ensures a snug fit, keeping the glove securely in place.

Why Choose a Velcro Closure?

Gloves with Velcro closures feature a strap that wraps around the wrist, pulling the two halves together. This design ensures a snug fit, keeping the glove securely in place.

Why Choose a Knit Wrist?

Crafted with a stretch-knit material usually extending 2″ to 3″ up the wrist. The knit cuff fits tight around the wrist shielding the hand from cold air and debris while holding the glove in-place.

Why Choose a Knit Wrist?

Crafted with a stretch-knit material usually extending 2″ to 3″ up the wrist. The knit cuff fits tight around the wrist shielding the hand from cold air and debris while holding the glove in-place.

Why Choose a Gauntlet Cuff?

Mirroring the characteristics of our safety cuffs but with an extended reach, the gauntlet cuff typically measures 5″ as opposed to 2″. This length offers not only forearm protection but also allows for sleeves to be comfortably tucked into the glove.

Why Choose a Gauntlet Cuff?

Mirroring the characteristics of our safety cuffs but with an extended reach, the gauntlet cuff typically measures 5″ as opposed to 2″. This length offers not only forearm protection but also allows for sleeves to be comfortably tucked into the glove.

Extra protection

Depending on the hazards you come across on the jobsite – you may need extra levels of protection. Like cut resistant liners, oil and water treatments, heavy duty rubber components, or even warm insulation to protect from winter elements.

Cutshield™

Cutshield™ is a cut resistant linear made from a blend of P-aramid, glass and polyester fibres. Available in cut levels A5, A6, A7.

Heavy-Duty TPR

In the world of impact resistance, Thermo Plastic Rubber (TPR) is the material of choice for back of hand protection. The elasticity of this rubber allows it to deliver optimal impact resistance, all the while maintaining a full range of motion and flexibility.

3M Recycled Thinsulate™

Industrial workers can go through numerous pairs of gloves each year due to rugged daily use, and the used products end up in landfills. We saw an opportunity to elevate the industrial PPE industry and be a market innovator by using recycled materials in winter glove lining. Teaming up with our long-time partner 3M, we’re now including Recycled Thinsulate lining in our gloves, enabling us to bring sustainability to the job site without compromising warmth or performance.

Leather Glove Myths

Did you know leather is not cut resistant?

Leather has excellent abrasion resistance, evident in its widespread use in motorcycle gear and construction wear. When faced with the roughness of construction materials or the rugged pavement during a bike skid, leather provides superior protection from abrasive forces. However, it’s crucial to note that while leather might excel in resisting abrasion, its cut resistance is very poor and, surprisingly, not much better than cotton. To address this, we incorporate a Cutshield™ liner in select gloves, elevating them to cut levels A5, A6, A7.

Leather has poor water resistance

Natural leather is limited when protecting against liquids; some leather types become stiff upon drying, reducing its flexibility and tactile sensitivity. Moreover, it provides no thermal protection when wet, leading to wearer discomfort and reduced mobility. To counter this, we apply our Dryhide™ treatment to certain gloves, ensuring up to 3 hours of water resistance.

Thicker is not necessarily better!

Contrary to popular belief, thicker leather doesn’t necessarily offer better protection than its lighter counterpart. In reality, heavier leather can hinder grip, movement, and dexterity, complicating tasks that involve tools or small components.

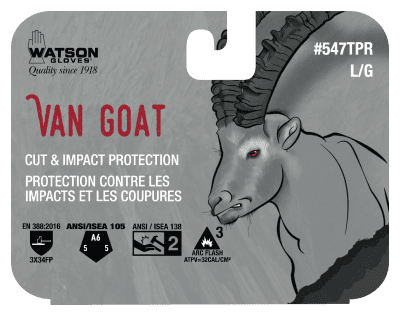

547TPR Van Goat

547TPR

Van Goat

Cutshield™ P-aramid/steel/polyester liner Dryhide™ oil and water resistant full-grain goatskin leather Drivers style with inset thumb Impact protection heavy duty… Read more »

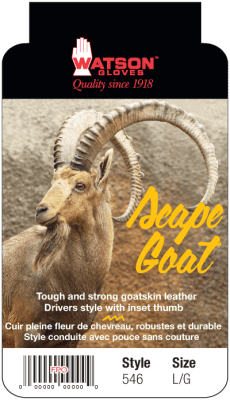

546 Scape Goat

546

Scape Goat

Full-grain goatskin leather Drivers style with ergonomic inset thumb Shirred elastic wrist Slip-on style cuff

597 The Duke

597

The Duke

Premium full-grain deerskin leather Drivers style with inset thumb Snug-fitting shirred elastic wrist and slip-on style cuff Heritage pull tab… Read more »

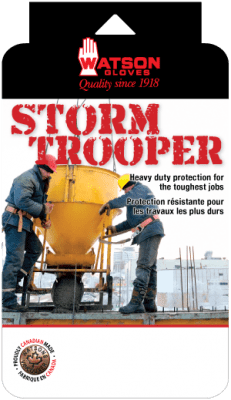

5782 Storm Trooper

5782

Storm Trooper

Full-grain deerskin leather back with Dryhide™ water and oil resistant cowhide leather palm Stitched with Kevlar® Flame resistant heavy duty… Read more »

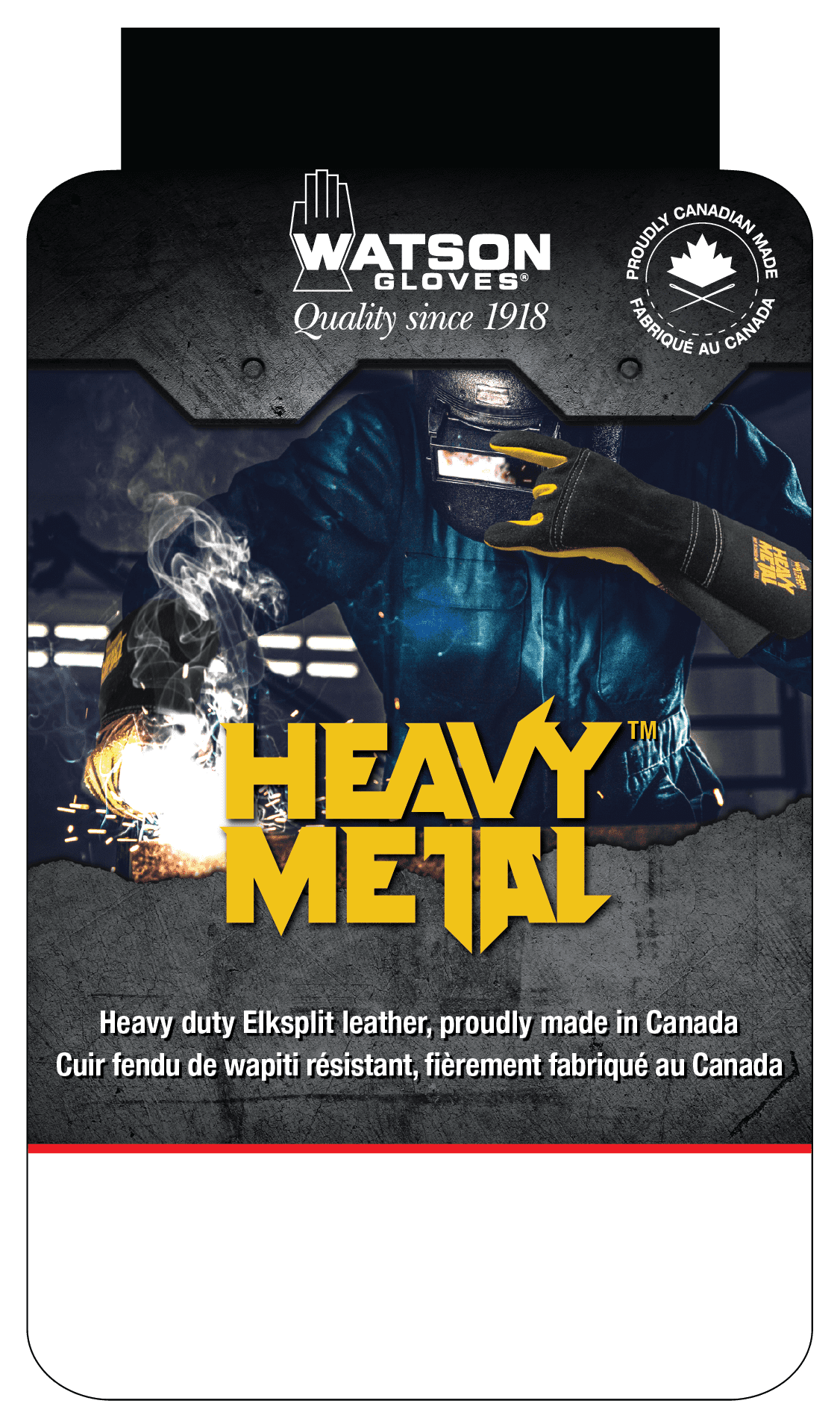

1039 Meltdown

1039

Meltdown

Elksplit leather back and palm Stitched with Kevlar® thread for strength and durability Cotton fleece lined back of hand for… Read more »

2780 Thrasher

2780

Thrasher

Split cowhide leather Stitched with Kevlar® thread for strength and durability Cutshield™ P-aramid/steel/polyester liner Full leather index finger and inset… Read more »

477 Wild Deerskin

477

Wild Deerskin

Full-grain deerskin leather Drivers style with inset thumb Shirred elastic wrist with slip-on cuff

567 Stagline

567

Stagline

Full-grain deerskin leather Canadian roper style with inset thumb Slip-on style cuff with snap back closure Unlined

1653 Man Handlers

1653

Man Handlers

Full-grain cowhide leather Drivers style Slip-on cuff with shirred elastic wrist Unlined